TL;DR: PVT keyboards are in customers hands; we’ve been working to ensure that issues found during the PVT run will be resolved before mass production starts next week; we’re working with BackerKit to get surveys out to everyone who preordered a keyboard from our website.

Hello from Oakland,

Since we last wrote in June, we’ve shipped the first 65 keyboards to Kickstarter backers who offered to help us test keyboards from the pilot run. At the same time, we’ve been working with the factory to get ready for Mass Production.

Mass Production starts next week

Mass Production is currently slated to start on August 25. The factory believe it will take them about a week to make the 2000 units to cover our Kickstarter preorders. After that, the keyboards will be tested in Shenzhen and be packed for their journey to our warehouse in California. Last time around, that took a little more than a week.

Once they arrive, we’ll spend a day or two doing additional spot checks to make sure everything looks right, and then we’ll ask the warehouse to start shipping them out as fast as they can.

On September 21, the factory will start “MP2"—the second mass production run. That will cover all post-Kickstarter preorders, as well as a whole bunch more. Right now, they’re estimating that MP2 will be done by October 7, though we’re looking at options for shipping them from China in blocks of 500 as they’re finished and tested.

We’ve started working with BackerKit to get preorders from our website into their system, so we can send out surveys to everyone who’s preordered. If you’ve preordered from our website, you can expect email from BackerKit as soon as the survey is ready. We’ll also tweet about it.

PVT Keyboards

Generally, the response to the PVT keyboards has been fantastic. We tried shipping the keyboards without "overpacking” them into larger cardboard boxes around the boxes. Initially, we were a little bit worried that the box might not offer enough protection, so we asked customers to tweet us some pictures of how things looked when they arrived. The packaging did its job—every keyboard arrived in good condition.

The point of a PVT run is to do a limited production run so you can fine-tune the process and figure out what sorts of problems you’re going to have. Using that information, you can update your assembly and test procedures and figure out if there are any design or materials issues that need to be addressed.

As expected, the keyboards haven’t been without their issues.

The biggest assembly/test issues we’ve run into are: soldering issues, wood surface issues, and keycap printing issues.

Soldering

We knew that there were a number of soldering problems with the PVT units, mostly due to the outsourced PCB Assembly factory they used to hit the PVT deadline. Even before we’d shipped, we’d identified some potential issues and they had done a first pass of additional quality checks. On a few keyboards, there were issues they’d missed, mostly related to bad solder joints. While PVT backers have been very understanding, this is something that can’t happen for mass production and the factory has told me that they’ve switched PCBA back to their standard supplier for mass production. At the same time, they’ve been working on additional manual QC steps to ensure soldering problems don’t slip through to shipped units for MP.

Wood surface

Some PVT users have found that the right hand enclosures for their keyboards have a slightly rougher surface than the left hand enclosure. We discovered this issue when we were checking the wooden enclosures before we shipped, but decided that it wasn’t a critical issue for PVT keyboards. We’ve told PVT customers who find it distracting that we’d be happy to swap out their enclosures once MP units are available. The reason this happened is that the wood factory made all of the left hand enclosures for PVT on one day and all of the right hand enclosures for PVT the next day. We’ve worked with the factory to document a “quality standard” for the wooden enclosures, using problems we found during PVT as examples. As the wood factory delivers batches of new enclosures to our factory, they’re doing a second check of them and sending units that don’t meet our requirements back to the vendor for rework.

Keycap printing

We’ve written before about the quality issues we’ve had with keycap laser engraving. So far, two PVT backers have reported keys swapped with each other, one backer has reported a key that had been lasered upside-down and one backer had a second ‘J’ key where his 'L’ should be. We swapped out the affected keys. Most of the keycap engraving issues were the result of a crazy manual process the factory was using to build sets of “good” keycaps from imperfect sets they got back from the laser engraving supplier. The factory has been working hard to improve the laser-engraving process. They’ve upgraded the painting jigs to make sure that the keycap alignment stays consistent on the laser engraver. They’ve built a custom tool to help make sure that the right keys get placed in the right positions for laser engraving and they’ve spent time training the technicians at the laser engraving factory to make sure that the keys are correctly placed on the jigs. We’ve also worked with them to clean up the placement of the legends a bit and slightly decreased the font size of all the key legends with words like “shift”, “num”, “return”, “alt”, etc. The factory has also been working with the keycap injection molding factory to correct some small errors in the keycap tooling.

Tight RJ45 cables

One issue some folks have run into is that short RJ45 cable require a lot of pressure to “lock” into the jacks on either half of the keyboard the first few times you do it. Other than the tight fit, the cables work fine. This is, we believed, caused by a tolerance issue between the jacks on the keyboard and the specific style of connector on the cable. The cable supplier has been looking for alternate connectors, but as yet, everything they’ve tried fits similarly. For the first mass production run, we’ll be sticking with these cables. If the factory manages to find a better option, we might change them for future runs.

Arrows of Ambiguity

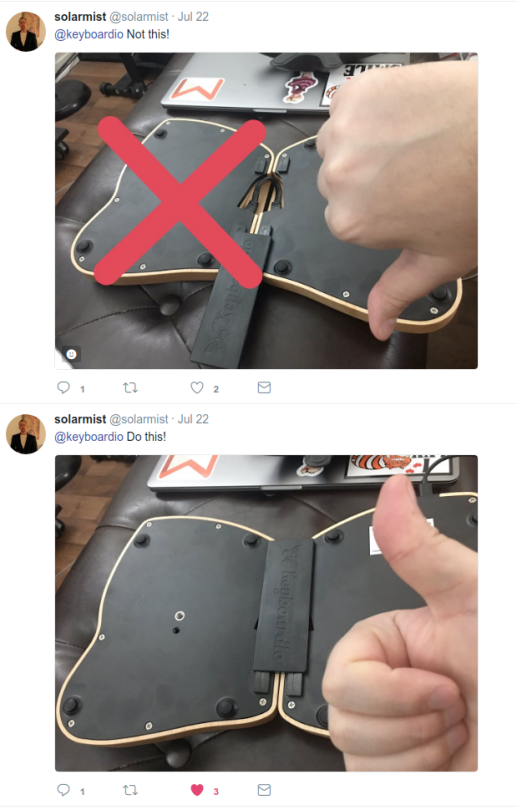

There is one design issue that we’re working with with the factory to correct. The sliding dovetail bar and rail system used to connect the two halves of the keyboard has been confusing to many users. The rails are tapered to ensure that the center bars slide on easily and click into place when slid in the correct direction. We printed arrows on the rails on the bottom of the keyboard to help show which direction to slide the keyboard into the center bars. Unfortunately, the arrows turn out to be confusing for some folks and it’s possible to force the bars far enough onto the rails to get stuck if you slide them in the wrong direction. Once you understand how the center bars are supposed to be connected, it’s pretty easy to keep doing it the right way.

We’ve updated the manual to better explain how to orient the center bars and have made a small design change to the rails that makes it impossible to slide the center bars on in the wrong direction. The factory is working hard to modify the injection molding tooling for the rails, but there’s a chance it won’t be completed before mass production for Kickstarter keyboards is done. If that’s the case, we’ll be providing Kickstarter backers with an additional reminder about the right way to connect the center bars as we ship their keyboards.

Software

Our PVT users have reported a number of issues with the firmware shipped with PVT keyboards. The big ones were that Media Keys and mouse button emulation didn’t work right on macOS. There were a few additional bugs reported around key repeat and LED modes. We believe we’ve resolved all of the above issues in the Mass Production firmware, which we had to send to the factory on Sunday. Of course, one of the things about the Model 01 is that we plan to continue to improve your keyboard’s firmware for a long time to come.

We also made a change to the keyboard’s “bootloader”, which is the program that’s responsible for letting you update the keyboard’s firmware. A number of PVT users have made changes to their keyboard’s firmware ranging from changing the key layout to writing cool new LED effects. A few of them have managed to 'brick’ their keyboards, making it impossible to get into the bootloader to reprogram their keyboards without unscrewing the enclosure and hitting the handy 'reset’ button we’ve put on the PCB. Because of this, we’ve added a new feature to the bootloader: If you hold down the 'prog’ key when you first connect your keyboard to your computer, it will enter the bootloader without trying to execute your possibly-broken firmware and you’ll have a little bit of time to flash a new program.

Along with all of this, we’ve been working to clean up the firmware source code, to fix a number of portability issues in the build tool, and to improve the code’s documentation. We’ve also started to write user-facing documentation. We’re tracking the documentation tasks here: https://github.com/keyboardio/Kaleidoscope/projects/1

There are a few 'major’ features which aren’t in the shipping keyboard firmware, because we aren’t confident they’re safe and stable enough. The two biggies are iOS 10 support and “Boot Protocol” keyboard support. We will provide both features as part of a free firmware update. (All firmware updates for the Model 01 will be free.)

- Apple appears to have made a change to how iOS 10 handles USB devices that say they want more than 100mW of power. In earlier versions, iOS would warn the user that the device wasn’t supported, but the keyboard would still work. Now, iOS refuses to let the device connect. We have a version of the firmware that works just fine (but without LEDs) on iOS, but need to do some engineering to make sure that we aren’t committing horrible atrocities against the USB stack on every other device to support iOS.

- The USB specification defines, essentially, two kinds of keyboards. Regular keyboards and “Boot Protocol” keyboards. Boot Protocol keyboards speak a simplified version of the USB keyboard protocol designed to be a little easier to implement in a computer’s BIOS or pre-boot environment. The downside of the Boot Protocol is that it doesn’t support “NKRO"—you can only press six keys at the same time. Our core libraries speak both keyboard protocols, but Kaleidoscope doesn’t yet do the right thing when the host wants to talk Boot Keyboard rather than NKRO keyboard. We ended up deciding that the changes required to make the keyboard do the right thing were too potentially destabilizing to add just before locking the firmware down for mass production. Getting this fixed is a high-priority task for Jesse, and we’re hoping to have it available as an update in the near future.

As always, our firmware lives at https://github.com/keyboardio/Kaleidoscope/ and new contributors are most welcome!

Builderscon 2017

Earlier this month, Jesse gave a talk at Builderscon about our experiences finding and working with a factory. The conference is primarily intended for the local audience and his talk was one of the few in English, though the conference organized simultaneous translation so folks actually laughed at some of his jokes.

All in all, the conference was really well organized and folks seemed pretty excited about the Model 01. One of the neatest talks Jesse saw, but didn’t really understand, was the story of one intrepid hacker’s adventure designing 3D models for a difference engine and 3D printing all the parts.

There’s already a video of Jesse’s talk up on Youtube. It’s about an hour long and is a reasonable (if slightly simplified) summary of the last two years of our backer updates.

Tokyo Meetup

The day after the conference, we held a little meetup at FabCafe in Shibuya, Tokyo. It all came together at the last minute and while we tried to email backers we knew were near Tokyo, we know it was short notice. It was lots of fun. FabCafe is a super-neat space. Their primary space is a trendy coffeebar with laser cutters. Hidden away upstairs is a proper makerspace with bigger tools and meeting space. As we got too big for the cafe, they very graciously offered us up the private space upstairs. About fifteen people came by to check out the Model 01 and to chat keyboards.

Boston Meetup?

We’re going to be in Boston for a family event from August 28-31 and are trying to figure out if we have the free time to host a little Keyboardio meetup. If we do, we’ll announce it over on https://twitter.com/keyboardio. (Alternatively, email kaia@keyboard.io with subject line "Boston meetup” and we’ll make sure you get an email with details.)

<3 j+k