TL;DR: We negotiated and signed a manufacturing agreement with a factory. Jesse got on a plane to China. Kaia wired a six figure deposit to Hong Kong. We have a first-pass manufacturing schedule. Long lead-time components are getting ordered on Monday or Tuesday. Our internal estimate on ship date is November 1.

Hello from Oakland & Shenzhen!

The past month has been eventful.

Kaia negotiated a manufacturing agreement with our preferred factory. We woke up one morning two weeks ago to find a stamped and countersigned PDF of the contract waiting in our email. You have no idea what a relief that was. On top of everything else, we’d already bought plane tickets for Jesse to head to Shenzhen to start work with the factory.

It’s still monsoon season in Shenzhen

Jesse got into Hong Kong airport at about 6AM on Wednesday morning. Maggie, our factory salesperson and her assistant Nick met him at the airport. They took a minibus to the Shenzhen border before switching to a cab out to the Bao'An airport area where Jesse’s AirBnB is. The rest of Wednesday was mostly just Jesse trying not to fall asleep before dinner time.

Thursday was eight hours of meetings with Jesse, Ken from HWTrek, Maggie, Nick, Mr Wang who heads the factory’s R&D team and, for the first half of the day, the factory’s General Manager.

The morning was mostly discussion of issues and risks the factory had identified, along with their proposals for resolving them. Maggie’s a big fan of “always having a Plan B.”

Components

The two most terrifying issues identified by the factory were around component “lead times"—how long it will take to get the components we need to build your keyboards. It’s not uncommon for some components of your project to have longer lead times than others. It’s the factory’s job to manage the supply chain and make sure that long lead time components get ordered early enough to not nuke your production schedule.

When we got the factory’s quotation for the project, no components had significantly long lead times. (Largely because we’ve been pretty careful to pick common high-volume components from known-good manufacturers wherever possible.) After we signed the contract and the factory started to schedule the project, they reverified all the component lead times and discovered that two of our required components are currently significantly backordered: the Atmel ATmega32U4 that’s the keyboard’s brain and the Matias keyswitches.

(Before you get too panicked, we’re pretty sure that we’ve figured out how to get the components we need on a sane schedule that won’t impact the production timeline by more than a week or two.)

Maggie and her team had prepared "Plan B” options for both components. The suggestions were reasonable proposals, but neither of them is what we promised you. In the case of the keyswitches, they recommended we consider MX-style keyswitches made by Kailh or TTC. Both are decent keyswitches, but they’re not the Matias switches we designed the Model 01 around. In the case of the controller, they recommended we consider a Cortex M0 processor from Cypress. Once again, it’s a pretty decent chip, but it’s not the “Arduino at Heart” Atmel microcontroller we promised and are excited about.

We reached out to Steve and Edgar at Matias to ask why the keyswitches that have always had a four week lead time were now going to take two months to deliver. It turns out that they’re in the middle of a design upgrade to make the switches feel less ‘wobbly’ and this involves taking the production line down for a month or so to retool. We’re excited that we’re going to be able to offer you the new and improved Matias switches. The key wobble has always been a part of ALPS-style switches like the Matias switches. We’ve never been able to notice the wobble while typing, but some customers have said they’d be happier with less wobble.

The factory is placing an order for somewhere north of a quarter million switches next week and is working with Matias to source a small quantity of switches to arrive somewhat sooner for our pilot run.

The situation for the Atmel ATmega32U4 is a little bit more interesting. If you follow the electronics industry, you may have heard that Microchip recently bought Atmel, the maker of the chip that powers the Model 01 and most of the classic Arduino boards. The Atmel distributor our factory has been working with told them that lead times had gone up from 3 days to 3+ _months_. Jesse and Maggie met with them on Friday morning and they told us that without a prenegotiated contract with Atmel/Microchip in the US, they…might not be able to help us out at all. Friday afternoon, Jesse and Maggie sat down with a second Atmel distributor whom Atmel’s marketing team in the US recommended to us. They haven’t made any promises, but said that on Monday or Tuesday, they should be able to make us some promises. We’ve also reached out to a contact at Microchip who’s working his internal connections to help us out. On top of that, we’ve located a friend of a friend who ordered a large number of the chips we need for a project that never happened. We’d strongly prefer to go through an official distributor, since that comes with additional support from Microchip/Atmel, but as a Plan B, it’s not so bad.

Design

The other design issues we discussed on Thursday morning were a lot less stressful.

We talked about the interconnect mechanism between the two halves of the keyboard. The factory’s R&D team has a design for a ratcheting hinge mechanism that looks pretty nice, if we can get it to fit nicely inside the Model 01. They’re going to do up drawings over the next week. If we like it, they’ll build a prototype. If it works well, that’s what we’ll go with. If it doesn’t work out right, we’ll be falling back to a slide-bar mechanism like we had on the aluminum keyboard prototype two years ago (different from the plate mechanism on the Kickstarter prototype). The only reason we moved away from that design in the first place was that a previous mechanical engineer asserted that it would be too expensive to manufacture. The factory…disagrees with that assessement.

We talked about the keyboard’s base plate. In our rececent prototypes, we’ve made it out of aluminum, with metal standoffs anchoring the PCB to the base plate. As we mentioned in previous updates, the factory wants to switch to a plastic base plate. This has a number of advantages. The biggest is probably that we’ll be able to embed the keyboard’s feet in the base plate, rather than have the screwed onto the bottom of the keyboard. The second benefit is that a high quality plastic base plate is much less likely to scratch your desk than the metal plates that have put some nice gashes in our desks. The third benefit is that it will be much easier to build in a bit of additional protection around the USB and RJ45 jacks. The fourth benefit is that it will be much lighter. (The metal keyplate that stabilizes the keyswitches is staying metal.)

We talked about the keyboard’s feet. Right now, Mr Wang’s team is working on drawings of feet that will give us all the tent and tilt angles we want. They should be done in a week. If they look workable, the factory will prototype them as part of prototyping the new plastic base plate.

We talked about keycaps. It looks like we’re going to be making them with a mix of ABS and Polycarbonate. The keycaps themselves will be a milky white color. The factory will then paint them black, laser engrave the key labels and then coat them in clear UV-protectant, which will help ensure that the paint won’t rub off. We’ll also be able to offer blank white keycap sets for folks who like the rainbow look. We haven’t yet nailed down the minimum order quantity for custom key legends, though we haven’t forgotten those of you who want Dvorak, Colemak, Bepó, AZERTY, QWERTZ, Nordic and other layouts.

That’s about where we broke for lunch.

Schedule

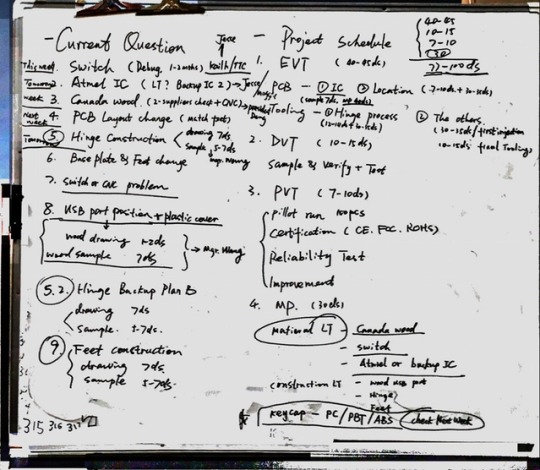

The afternoon meeting was the main event. Maggie walked us through the draft schedule. It’s optimistic and aggressive. That’s another way of saying that if things go wrong, the schedule will slip. We tend to believe the longer end of the schedule is more likely than the shorter end of the schedule. We’ll keep you updated as we work through the schedule.

Manufacturing schedules are typically broken into four phases. The names and exact tasks in each phase vary. Our factory’s process is, conveniently, the one we’re most familiar with: EVT (Engineering Verification Test), followed by DVT (Design Verification Test), followed by PVT (Production Verification Test), followed by MP (Mass Production).

The main activities in EVT are electrical and mechanical engineering tasks. On the EE side, we need to finalize our component choices, make some small tweaks to the circuit board designs to accomodate the mechanical changes, make and test final prototype PCBs, and then make the tooling for the PCB manufacture.

On the mechanical side, there’s a lot more to do. We need to finish the designs for the new feet, interconnect and baseplates. We need to make prototype samples of all of those parts, as well as the keycaps, key plates. After signing off on the design, the factory’s R&D team will design the injection moulding and metal stamping tooling for the keycaps, feet, keyplate, and bottom enclosure, as well as the “fixtures” used for assembling the keyboard. These are individual or low-volume parts that make sure that the keyboards get assembled the same way each and every time.

As currently scheduled by the factory, EVT is expected to take 40-45 days. Of all these tasks, the keycap tooling is the bit we’re expecting to have the highest likelihood of slipping. It’s an incredibly labor-intensive task that’s also incredibly fiddly.

DVT is mainly about actually testing out that tooling created during EVT and verifying that yes, keyboards made with the tooling look, feel and work correctly. At the same time, we’ll be finalizing the boxes, mini-manual, cables, screwdrivers and other things that will come with your keyboards.

DVT is scheduled to take 10-15 days.

PVT is, as the name implies, when we verify production. 100 keyboards will get made on the production line. We’ll work with the factory to debug and optimize the assembly and test process. A few of these keyboards will be used to test the keyboard and get us our FCC and CE certifications. Most of the rest of them will be sent out to intrepid Kickstarter backers. As we get closer to PVT, we’ll be asking for volunteers who are willing to spend a week or two making sure we haven’t overlooked anything catastropic before we move on to Mass Production.

PVT is scheduled to take 7-10 days.

Mass Production is the bit most folks think of when they hear about manufacturing. In a few short weeks, stacks of wood, reels of components and big bags of plastic pellets will be magically transformed into thousands of Keyboardio Model 01s.

Mass Production is scheduled to take 30 days.

After Mass Production, our logistics company will pick up a truckload of keyboards, shepherd it across the border to Hong Kong and onto a container ship or a plane on their way to you. We’ll make a final call about whether the keyboards are going by airfreight or by sea as we get closer to mass production. Cost and scheduling both play into the decision and we don’t yet have final numbers on either front.

Once you add up all the numbers on that schedule proposed by the factory, you get something in the range of 87 to 100 days from “go” to when keyboards roll out of the factory’s gate.

“Go” is tomorrow: Monday, July 11. The factory has pegged October 19 as their estimated ship day. That’s at the short end of their 87-100 day timeline once you factor in 10 days of Chinese national holidays. We are cautiously optimistic, but our internal guess is that the earliest possible date keyboards could ship out from China is probably closer to November 1.

The factory has prepared a project tracking spreadsheet, which you can access a snapshot of here. From here until ship day, we’ll be sharing the latest copy of this spreadsheet in every backer update. We will be removing the names of our manufacturing partners and folks who aren’t Keyboardio staff, as well as specific costs, but won’t be changing dates or and of the words in the schedule. Some things will look a little funny, mostly just because they’re translated from Chinese. (For example, the tooling for the PCBs isn’t actually a 'PCB Injection Mould’)

<3 j+k