TL;DR: Kickstarter units have almost all shipped; most post-Kickstarter pre-orders have shipped; extra keycap sets are expected to ship sometime in April

Hello from Oakland,

When we last wrote a public update on January 25, we told you that assembly of MP2 keyboards had been completed and that assembly of MP3 was in progress.

Our factory was due to close for Chinese New Year on February 8. We were concerned that, if anything at all went wrong, no MP2 keyboards would ship out until the end of February, so Jesse got on a plane to Hong Kong for a last-minute trip to help the factory work through any issues.

In the end, the factory shipped out about 1000 keyboards as part of MP2 and about 700 keyboards as part of MP3. Originally, they had planned to ship 1000 keyboards as part of MP3, but they ran out of time. More accurately, they ran out of workers—by the time Jesse left China on the evening of February 6, most of the factory’s assembly and QC workers had already gone home. Three hundred keyboards were left partially assembled and waiting for testing. Those keyboards will ship as part of MP4.

As of early March, we have shipped keyboards to every Kickstarter backer who had completed their survey as of March 1, with the exception of “Mahogany Limited Edition” backers and our one customized ten-pack backer. (We’re still pushing on our wood suppliers to get the mahogany enclosures made, but are starting to explore other options.) We’ve also filled the majority of post-Kickstarter orders.

As of now, we’re within 600 orders of being caught up with preorders.

We’re currently currently expecting the MP4 production run to be ready for our third-party quality control agency to check on April 12. This is a bit later than we’d expected, but the factory has told us that they’re doing some work to improve circuit-board assembly and would rather slip a few days than ship a few more defective keyboards. Right now, MP4 is estimated to be about 500 keyboards. When we know exactly how many keyboards we’re getting, we’ll be in touch with everyone getting an MP4 keyboard to reconfirm your address. The factory has told us to expect MP5 before the end of April.

Keycap sets

The factory has told us that the injection molding shop responsible for the keycaps have been dragging their feet on the replacement keycap sets, claiming that they have a significant backlog of orders from before Chinese New Year. They’ve been telling us that they promise to have the extra keycap sets ready to send to the painting shop by the end of March. From there, they’ll be laser engraved and packaged. Once the factory starts packaging the keycap sets, we’ll be in touch with everyone expecting keycap sets to reconfirm your addresses.

Right now, we’re expecting to ship out keycap sets by postal mail, either from Hong Kong or directly from China. (Sending them by an express courier would likely cost as much as, if not far more than, the keycaps.)

Spotlight: user-created keycaps

One intrepid user, Stefan Eichberger, has actually designed and 3D printed two of his own custom keycaps for the Model 01. One of his keycaps is functional. The other is just fun.

His first keycap was a modified function key with a custom cutout, designed to be a little bit more comfortable for how he types on the Model 01.

Stefan’s second key was an updated Prog key, featuring a very important productivity tool that the Model 01, as shipped, was seriously lacking.

You can read more about Stefan’s work here: https://community.keyboard.io/t/3d-printing-keycaps/1151/2

If you’re thinking of crafting custom keyshapes for your Model 01, please do heed Stefan’s warnings about damaging your keyswitches. It’s very, very easy to destroy an ALPS-style keyswitch by snapping off a 3D-printed keycap’s stem inside the switch’s slider.

Update on wood suppliers

MP2 keyboards shipped with a mix of the best enclosures from the original wood Supplier and enclosures from Supplier C. MP3 quiet-click keyboards shipped with enclosures from Supplier A. MP3 loud-click keyboards shipped with enclosures from Supplier A.

When Supplier C’s first 500 enclosures arrived at our factory in the middle of December, the factory discovered that the supplier had not sized the cutouts for the USB C jacks correctly, so sent the parts back to be reworked. In early January, Supplier C delivered the second 500 sets they owed us. Later in January, they redelivered the first 500. Between MP2 and MP3, we shipped about 600 keyboards with enclosures from Factory C. There are about 200 more known-good enclosures from Supplier C in the factory’s warehouse, which will be used for MP4.

Sitting in our factory’s storage, there are currently 191 sets from Supplier C which we believe do not meet our quality standards. 60% of them appear to have warped slightly. 30% of them have significant discolorations. 20% of them still have USB C cutouts that aren’t sized correctly. Over the course of the past month, we’ve been negotiating with Supplier C to try to get them to rework or replace the defective enclosures.

Supplier A delivered their 1000 sets a little bit behind Supplier C, which is why their enclosures didn’t ship until MP3. As the factory started to assemble keyboards with their enclosures at the beginning of February, they discovered that nearly half of them had significant amounts of glue inside the screw holes used to attach the enclosures to the baseplates. After a quick meeting where we talked through mitigations and how to rework the defective parts, Supplier A picked them up from the factory and worked over the weekend to repair as many as they could. The next week, they delivered 300 ‘good’ sets back to our factory. The remaining 200, they deemed unsalvageable and promised to replace as quickly as possible after Chinese New Year. In the end, those 200 replacement sets were delivered to our factory at the beginning of this week.

The original wood supplier has, we’ve been told, completed 300 more sets to mostly fulfill their original obligation to us. However, our factory reports that the quality of these enclosures matches what they’ve shipped us in the past and that we shouldn’t expect to see more than a very small number that pass inspection. While Jesse was in China, he finally got his hands on a “dark-stained” wooden enclosure from the original supplier. The coloring looked ok, but when we looked carefully, we realized that the supplier hadn’t stained the parts like we talked about. Instead, they’d airbrushed them with a red-brown paint. That, as they say, was the end of that.

Update on manufacturing defects

In the last update, we wrote about the various issues with MP1 keyboards that customers had reported to us. We don’t have any significant new issues to report on that front, though the mix of issues has changed somewhat. As you might expect, we’ve seen fewer wood issues with MP2 and MP3 keyboards. At the same time, we saw more keyboards from the MP2 and MP3 batches non-functional on arrival than we had during MP1. We believe that there are a few potential causes. First, workers were likely a little bit more rushed in the leadup to the holiday and may not have been as diligent as we’d have liked. Second, at least in the case of MP2, surface-mount assembly of the circuit boards was completed along with MP1, but wave soldering was done months later. There is a chance that the long delay before running through the second oven could have damaged some chips. Going forward, they will make sure they tightly control the time between surface mount assembly and wave soldering. Third, we found out after the fact that the factory had not put every MP2 and MP3 keyboard through a 72 hour aging test as they had for MP1. For MP2 and MP3, they only tested a small percentage of the production runs. They’ve promised that, going forward, every keyboard will be run through a full 72 hour aging test.

We previously wrote about 'warped’ Model 01 stands. At the time, we believed the issue was caused by plastic parts that came out of the injection molds slightly deformed. Since that time, we’ve discovered that in almost all cases, the problem is simply that the factory’s assembly line workers overtightened the screws inside the stands. We’ve developed an at-home procedure for repairing a defective stand. You can read about it here: https://community.keyboard.io/t/a-possible-fix-for-wobbly-stands/1143/8

We’ve previously written about keychatter that some customers have seen with MP1 and MP2 quiet-click keyboards. Starting with MP3, all quiet-click keyboards have shipped with new Matias switches lubricated with a dry teflon instead of the old jelly-like grease that had a tendency to migrate to the electrical contacts.

We’ve been working with MP1 and MP2 customers whose keyboards develop keychatter (the form of either repeating keystrokes or missed keystrokes) to repair or replace the defective switches. We’ve also been experimenting with a software solution that changes how we read and process the electrical contact data from the keyswitches. We’ve got some more work we want to do on that front, but so far, it does seem to greatly reduce keychatter problems.

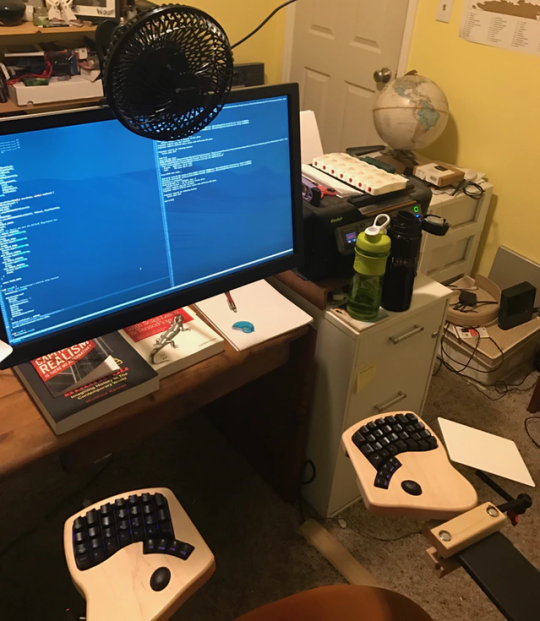

Spotlight: Captain’s chair

We’ve been waiting for this one.

Chris Vincent (no relation) posted about his custom Model 01 setup earlier this week. It’s awesome.

Chris built custom mounts to connect his Model 01 and an Apple Magic Trackpad to his desk chair. He spent time running extension cables overhead to keep them out of the way while he works, and added articulating arms to allow him to adjust the position of the Model 01 on the fly.

You can read more about his setup here: https://community.keyboard.io/t/my-captains-chair/1297/4

We love to see how people are using the Model 01 and making it their own. If you’ve done something neat or have ideas for a Model 01-related project, please post about it at http://community.keyboard.io

Shipping MP2 and MP3

We shipped PVT and MP1 keyboards from California. Due to a number of delays and expensive shipping errors, the experience was… not as smooth as we would have hoped, so we resolved to see if we could do better for MP2. Overall, we like the new shipping partner a lot better, but there are some things we’re hoping to improve for MP4.

When he landed in Hong Kong in late January, Jesse visited one potential new partner’s warehouse and liked what he saw. It took a few days to get the paperwork sorted out and a week later, 1000 keyboards were loaded on a truck in Shenzhen for a quick journey across the border to Hong Kong.

One of the advantages of our new shipping partner is that they allow us to choose between more than a dozen shipping options on a per-package basis. Most of our customers are in the US, so we ended up with a special hybrid solution for keyboards destined for the States. Each keyboard was individually labeled for delivery in Hong Kong, then all the US orders were consolidated onto pallets and shipped by air to a warehouse near Chicago, where they were handed off to DHL, who brought each keyboard to a Post Office near its eventual destination and handed it off to USPS for last-mile delivery. On the whole, this went ok. Not amazing, but ok. We ran into a couple of problems. First, we sent you shipping numbers too early. In the past, we’ve sent out shipping numbers only after keyboards had been handed off to FedEx. In this case, we sent you shipping numbers before your keyboards left Hong Kong. Our shipping partner’s package tracking page didn’t take into account the time needed to get your keyboards from a warehouse in Hong Kong to a warehouse in Chicago which set an… unreasonable expectation of when your keyboard might arrive. On top of that, MP3 keyboards were handed off to the international carrier just before Hong Kong had their Chinese New Year holiday, so boxes sat in Hong Kong for longer than we expected. Once packages got to DHL, a small number of them took an unreasonably long time to get to USPS. The worst problem only affected about 4-5 people who had mistyped their zipcodes. Due to a design flaw in our shipping partner’s software, city names that didn’t match the entered zipcodes were silently “corrected” as shipping labels were printed, leading to packages being marked as undeliverable and being “returned to sender.” We’re still trying to find four of them.

For the rest of the world, shipments went out by a mix of UPS, DHL, Aramex, DPEX, SF Express, and, in a very few cases, HK Post.

Many of the MP3 UPS shipments took far longer than we’d been promised. As it turned out, UPS was dramatically over capacity around Chinese New Year and we drew the short straw. More than 100 keyboards sat in a warehouse, unable to enjoy the New Year’s festivities. UPS shipments to Europe also suffered from confusing tracking updates—UPS now offers electronic customs preclearance. This means that package information is sent in advance of the actual package. This is great because it can save multiple days of transit delays due to customs agencies. This is…less than great…because UPS reports the customs-related tracking updates as having happened in the destination country, which leads to an update history that suggests that a package got to you and was then sent back to Hong Kong to begin its journey again.

A number of shipments to France, the Netherlands and the UK went by Aramex. We’re sorry. We didn’t know. They won’t be getting any more of our European business. They charged you extremely high handling fees, failed to contact you to arrange delivery, claimed they had attempted delivery when they hadn’t, and have still failed to figure out that they’ve finally delivered all the packages we entrusted to them.

Shipping and fulfillment is one place where first-time creators can really blow their budget. While the ability to ship just about anything to ato just about anywhere on earth in undoubtedly one of the wonders of modern life, the costs can be staggering. So far, despite getting huge discounts from our shipping partners, we’ve spent over $115,000 on shipping alone. This averages out to a cost of a bit more than $40 a keyboard.

Once pre-orders have been filled, we intend to ship most of our inventory by ocean freight to a U.S. warehouse, and then fulfill U.S. orders from there. International orders will probably still ship from Hong Kong. This should lower our total cost of shipping a little bit, but most importantly it will give us the capability to get keyboards to U.S. customers a few days after they order.

What’s next

We’re still pretty focused on getting the rest of your Model 01s (and your keycaps) shipped and helping you resolve any issues you find as you get up and running, but we’re starting to think a bit more about what we’re going to do next.

Right now, we’re leaning toward something more portable, a little bit more approachable and just a tiny bit easier to manufacture. We’re also contemplating a few accessories for the Model 01. As we figure out what we’re doing, you can rest assured that we’ll tell you all about it ;)

<3 Jesse + Kaia